ABB PFTL 101A-2.0kN

Here’s the professional English translation of your ABB PFTL 101A-2.0kN force sensor introduction:

**ABB PFTL 101A-2.0kN Force Transducer Introduction**

**1. Product Overview**

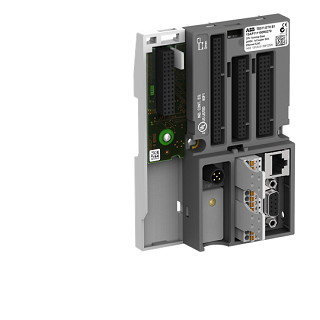

The **ABB PFTL 101A-2.0kN** is a high-precision **force transducer** from ABB's **PFTL series**, designed for industrial automation, testing and measurement applications. It provides accurate measurement of **both tension and compression forces**, with a maximum capacity of **2.0kN (approximately 204kgf)**.

**2. Key Specifications**

- **Model**: PFTL 101A-2.0kN

- **Measuring range**: 0~2.0kN (tension and compression)

- **Output signals**:

- Analog outputs (e.g., ±10V, 4~20mA)

- Digital outputs (optional, e.g., RS485, CAN bus)

- **Accuracy**: ±0.1% FS (full scale)

- **Overload capacity**: Typically 150% FS (higher for short-term)

- **Operating temperature**: -10°C to +70°C (industrial grade)

- **Protection rating**: IP65 (dustproof and water-resistant)

- **Mechanical interface**:

- Threaded holes at both ends (e.g., M8/M10) for easy installation

**3. Core Features**

a. **High-Precision Measurement**

- Utilizes stable strain gauge technology with excellent long-term stability and low temperature drift.

b. **Robust Construction**

- Made of stainless steel or alloy steel, offering impact resistance and corrosion protection for harsh industrial environments.

c. **Multiple Output Options**

- Supports both analog (voltage/current) and digital communication, compatible with PLCs and data acquisition systems.

d. **Flexible Installation**

- Compact design allows integration into test benches, robotic arms, tension control systems, etc.

**4. Typical Applications**

- **Industrial Automation**: Robotic gripping force control, assembly line pressure detection.

- **Testing & Quality Control**: Material strength testing, product durability testing.

- **Process Control**: Tension control (e.g., cables, textiles, packaging machinery).

- **R&D Laboratories**: Mechanical research, dynamic force monitoring.

**5. Supporting Equipment**

- **Signal conditioners** (e.g., ABB matching amplifier modules).

- **Data acquisition systems** (e.g., PLCs, DAQ modules).

- **Calibration equipment** (regular calibration required to maintain accuracy).

**6. Important Notes**

- Avoid overloading to prevent sensor damage.

- Ensure force direction aligns with the sensor's axis during installation to avoid side loads.

- Perform regular calibration (recommended annually or based on usage frequency).

**Contact us if you need this product!**