Schneider ATV630D45N4

### **Introduction to Schneider ATV630D45N4 Variable Frequency Drive**

#### **1. Product Overview**

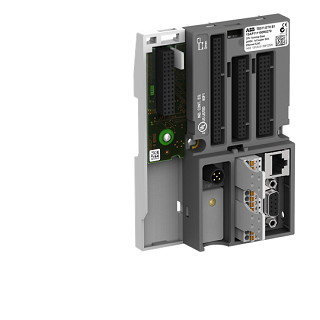

The **ATV630D45N4** is a high-performance variable frequency drive (VFD) from Schneider Electric’s **ATV600 series**, designed for industrial motor control and suitable for speed regulation of three-phase asynchronous motors.

- **Rated Power**: 45 kW

- **Rated Current**: 90 A

- **Input Voltage**: 380~480 V AC (3-phase)

- **Output Frequency Range**: 0.1~500 Hz

- **Protection Rating**: IP20 (requires installation in a control cabinet)

- **Control Modes**: V/F control, Sensorless Vector Control (SVC), Closed-loop Vector Control (optional encoder feedback)

#### **2. Key Features**

a) **High-Performance Motor Control**

- Supports **Sensorless Vector Control (SVC)**, providing high starting torque (150% rated torque @0.5Hz).

- Optional **Closed-loop Vector Control** (requires external encoder) for high-precision speed/torque control applications.

b) **Energy Saving & Smart Management**

- Built-in **energy-saving algorithm** to optimize motor efficiency and reduce power consumption.

- Supports **PID regulation**, ideal for pump, fan, and variable load applications.

c) **Rich Communication Interfaces**

- **Built-in Modbus RTU** (RS485)

- Optional fieldbus cards for **Ethernet/IP, Profibus DP, CANopen** (requires expansion modules).

d) **High-Reliability Design**

- Built-in **DC reactor** to reduce harmonic interference.

- Supports **braking units** (external braking resistor) for frequent start-stop or heavy-duty applications.

- **Overload Capacity**:

- 150% rated current for 60 seconds

- 180% rated current for 3 seconds

e) **User-Friendly Operation**

- **7-segment LED display** + **graphical control panel** (optional)

- **SD card parameter backup** for quick commissioning and maintenance.

#### **3. Typical Applications**

- **Industrial Pumps & Fans** (energy-saving control, PID regulation)

- **Conveyors & Material Handling** (smooth start-stop, multi-motor synchronization)

- **Machine Tools & Processing Equipment** (high-precision speed control)

- **Hoisting & Winding Equipment** (torque control, braking management)

#### **4. Installation & Wiring**

- **Mounting Method**: Wall-mounted (must be installed in a control cabinet with proper ventilation).

- **Cooling Method**: Fan-cooled (built-in cooling fan).

- **Terminals**:

- Power Input: L1/L2/L3 (3-phase 380~480V AC)

- Motor Output: U/V/W

- Control Terminals: Analog I/O, digital I/O, relay output, etc.

#### **5. Accessories**

- **Braking Resistor** (e.g., VW3A77502)

- **Communication Expansion Card** (e.g., VW3A3607 - Profibus DP)

- **Graphical Control Panel** (e.g., VW3A3316)

#### **6. Precautions**

**Overload Protection**: Set parameters according to motor rated current to avoid prolonged overload operation.

**Cooling Requirements**: Ambient temperature ≤50°C; ensure proper ventilation.

**EMC Compliance**: Recommended to install input reactors or filters to reduce electromagnetic interference.

If you need this product, feel free to contact us!