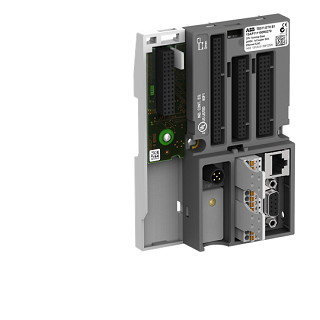

ABB TB820V2

ABB TB820V2 Product Introduction

**1. Product Overview**

**Model**: TB820V2

**Series**: ABB **Tension Control** Series

**Type**: **Tension Controller**

**Applications**: Industrial processes requiring precise tension control, such as web processing, printing, packaging, film stretching, and wire/cable production.

**2. Key Features**

**High-Precision Tension Control**

- Utilizes **closed-loop control algorithms**, supporting both **direct tension control** and **indirect tension control** (via speed/torque adjustment).

- Control accuracy up to **±0.5%**, ideal for high-speed, high-precision production.

**Multiple Operation Modes**

- **Speed Mode**: For constant-speed unwinding/rewinding.

- **Torque Mode**: Directly controls material tension.

- **PID Adjustment**: Automatically compensates for tension fluctuations (e.g., material thickness variations).

**Compatibility with Various Sensors**

- Supports **analog signals (0-10V / 4-20mA)**, **digital encoders**, or **direct tension sensors** (e.g., Load Cell).

**Integrated Automation Interfaces**

- **Fieldbus Communication**: PROFIBUS DP, Ethernet/IP, Modbus RTU/TCP.

- **I/O Expansion**: Connects to external PLCs or HMIs for automated production line integration.

**User-Friendly Operation**

- Optional **7-inch touchscreen** for quick parameter setup and real-time monitoring.

- Built-in **fault diagnostics** and **historical data logging**.

**3. Technical Specifications**

| **Parameter** | **Specification** |

|------------------------|----------------------------------------------------------------------------------|

| **Control Method** | Closed-loop PID control, Speed/Torque Mode |

| **Input Signals** | Analog (0-10V/4-20mA), Encoder (A/B/Z phase), Load Cell (mV/V) |

| **Output Signals** | Analog (0-10V/4-20mA), Relay Output, RS485 |

| **Communication** | PROFIBUS DP, Ethernet/IP, Modbus RTU/TCP |

| **Power Supply** | 24V DC or 110-230V AC (model-dependent) |

| **Protection Rating** | IP20 (requires cabinet installation) |

| **Operating Temp.** | 0°C to +50°C (non-condensing) |

| **Certifications** | CE, UL, cULus |

**4. Typical Applications**

- **Printing Industry**: Constant tension control for newspapers and packaging materials.

- **Film Stretching**: Winding/unwinding of PET and BOPP films.

- **Wire/Cable Production**: Precise tension adjustment for copper wires and optical fibers.

- **Paper Processing**: Slitting and rewinding of tissue paper and corrugated board.

**5. Competitive Advantages**

| **Feature** | **TB820V2** | **Traditional PLC + Inverter Solution** |

|------------------|--------------------------------------|-----------------------------------------|

| **Control Accuracy** | ±0.5%, optimized for tension control | Lower accuracy (±2-5%), programming-dependent |

| **Response Time** | Millisecond-level dynamic adjustment | Limited by PLC scan cycles |

| **Setup & Debugging** | Pre-loaded tension algorithms, simplified parameter wizard | Requires custom logic development |

| **Maintenance** | Modular design, easy fault tracing | Complex system, difficult troubleshooting |

**6. Important Notes**

**Selection Tips**:

- Confirm **material type** (e.g., metal foil, film, paper) and **maximum tension range**.

- Select compatible **sensor type** (encoder/Load Cell).

**Installation Requirements**:

- Avoid vibration and electromagnetic interference (e.g., keep away from high-power inverters).

- Ensure **shielded grounding** of sensor cables to prevent noise.

**Configuration & Optimization**:

- Use **auto-tuning** for quick PID parameter matching.

- Advanced parameter configuration via **PC software (TB-Configurator)**.

**Contact us if you need this product!**